Splendid Industries: Torque Equipment

Torque equipment plays an essential role across a broad spectrum of industrial sectors, from automotive manufacturing and aerospace engineering to energy production and heavy construction. As industries strive for higher efficiency, improved product quality, and enhanced worker safety, the demand for precise and reliable torque tools has grown steadily. Splendid Industries, a hypothetical or emblematic company in this domain, represents the convergence of engineering excellence, quality management, and market-responsive innovation. This essay examines the significance of torque equipment in modern industry, the technical and operational considerations that define high-performing torque tools, and the strategic approaches a company such as Splendid Industries might employ to lead the market—from product development and quality assurance to customer support and sustainability.

The Role of Torque Equipment in Industry

Torque—a measure of rotational force—is a fundamental parameter in the assembly and maintenance of mechanical systems. Correct torque application ensures the integrity of bolted joints, minimizes the risk of component failure, and optimizes load distribution. Under-torquing can lead to joint slippage, loosening, and fatigue failures; over-torquing can strip threads, deform fasteners, and introduce unacceptable stresses. Consequently, torque equipment is indispensable for industries where mechanical reliability and safety are critical.

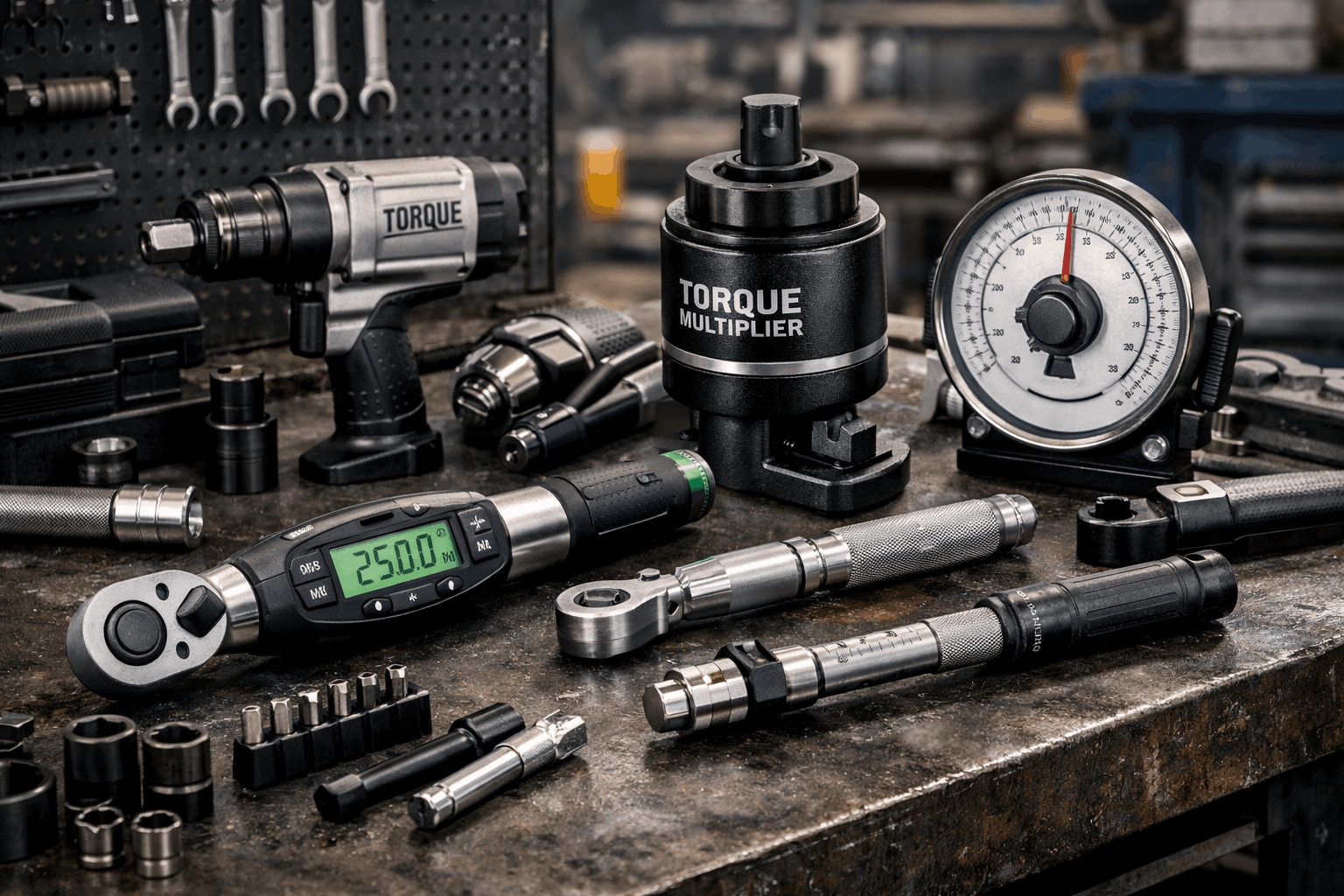

Common categories of torque equipment include manual torque wrenches, pneumatic and electric torque tools, hydraulic torque wrenches, torque multipliers, and advanced digital torque analyzers and controllers. Each category addresses distinct use cases: manual wrenches for low-volume or portable tasks, pneumatic and electric tools for production-line speed and repeatability, hydraulic tools for high-torque bolting in heavy industry, and digital systems for traceability and process control. In manufacturing environments, torque equipment integrates with production management systems and quality control protocols to ensure consistent assembly parameters and to provide records for compliance and warranty purposes.

Technical Considerations for High-Quality Torque Tools

Precision and accuracy are the primary technical benchmarks for torque equipment. Achieving and maintaining specified torque values requires calibrated mechanisms, minimal hysteresis, and robust sensors or mechanical linkages. Torque accuracy is generally expressed as a percentage of full-scale reading; high-quality tools typically deliver accuracy within ±2% to ±4%, depending on the type and application.

Ergonomics and ease of use are also central to tool performance. Repetitive bolting tasks expose operators to fatigue and the risk of cumulative trauma disorders; therefore, design features such as balanced weight distribution, reduced vibration, comfortable grips, and straightforward controls significantly affect user efficiency and health. Tools that are intuitive to set and monitor reduce human error and improve throughput.

Durability and serviceability are critical for minimizing total cost of ownership. Materials selection, sealing against contaminants, resistance to corrosion, and protective coatings contribute to longevity in demanding environments. Additionally, modular designs that allow for straightforward replacement of wear parts, accessible calibration interfaces, and a robust spare-parts supply chain enhance uptime and reduce lifecycle costs.

Data connectivity and digital capabilities increasingly define the cutting edge of torque equipment. Smart torque tools equipped with sensors, onboard memory, wireless connectivity, and secure data logging enable real-time monitoring and process control. They facilitate traceability through timestamped torque records, user identification, and integration with quality management systems (QMS) and manufacturing execution systems (MES). In regulated industries—such as aerospace and pharmaceutical manufacturing—such traceability is not only advantageous but often required.

Market Dynamics and Competitive Positioning

The torque equipment market is shaped by both technological innovation and shifting industrial demands. Automation and Industry 4.0 trends are pushing manufacturers to provide torque solutions that integrate seamlessly with robotic systems, automated fastening cells, and centralized control software. As production processes become more automated, suppliers must ensure their tools can operate reliably under programmatic control and communicate diagnostic and process data.

A company like Splendid Industries must navigate competitive pressures by differentiating through quality, innovation, and services. Product differentiation can arise from superior accuracy, enhanced digital features, robust warranty and calibration programs, and targeted offerings for niche markets (e.g., subsea bolting, nuclear-grade fasteners, or precision aerospace assemblies). Strategic partnerships with system integrators, robotics firms, and large manufacturing customers can expand market reach and embed technologies into end-to-end production lines.

After-sales service, training, and calibration are pivotal competitive levers. Customers purchasing torque equipment often value comprehensive lifecycle support—scheduled calibrations, rapid-response repairs, user training, and software updates. Splendid Industries can develop recurring-revenue models through service contracts, certified calibration centers, and subscription-based software services for data analytics and compliance reporting.

Quality Management and Regulatory Compliance

High-quality torque equipment manufacturers operate under rigorous quality management systems (e.g., ISO 9001) and often conform to industry-specific standards (e.g., ASME, DIN, ASTM). Calibration and traceability to national standards are mandatory practices; accredited laboratories and documented calibration chains ensure measurement validity. Documentation—such as calibration certificates, inspection reports, and maintenance logs—supports customer confidence and regulatory audits.

Risk management is also integral. Manufacturers must analyze failure modes (e.g., Seal degradation, sensor drift, electronic interference) and implement design redundancies and protective measures. Safety standards and ergonomics regulations similarly influence product development and factory practices. For products deployed in critical applications—such as pressure vessels, structural assemblies, or flight-critical components—stringent validation and certification processes are required.

Innovation and R&D Strategy

Sustained leadership in torque equipment depends on consistent investment in R&D. This includes advances in sensing technologies (e.g., MEMS-based torque sensors), electronics miniaturization, battery and power management for cordless tools, and algorithms for torque control and adaptive fastening. Machine learning methods can analyze usage and performance data to predict maintenance needs, detect anomalies, and optimize fastening sequences for quality and speed.

R&D also explores materials science to improve strength-to-weight ratios, corrosion resistance, and wear characteristics. Integration with robotics and automated systems requires co-development efforts—creating tool interfaces, communication protocols, and controllers that permit precise, repeatable fastening under varied orientations and speeds.

Market-driven innovation can focus on user-centric features: simplified user interfaces, multilingual displays, customizable playlists for fastening sequences, and enhanced safety interlocks. Additionally, expanding into software ecosystems—providing APIs and SDKs—enables system integrators and customers to incorporate torque tools into broader automation and analytics platforms.

Sustainability and Operational Responsibility

Environmental and social responsibility have become central to industrial strategy. Splendid Industries can reduce its ecological footprint by improving manufacturing efficiency, minimizing waste, and selecting recyclable materials and lower-impact coatings. Energy-efficient electric tools and power management features reduce operational energy use. Responsible supply chain management—including conflict-free sourcing, supplier audits, and adherence to labor standards—strengthens brand reputation and mitigates operational risks.

Lifecycle thinking extends to product design: tools built for durability and reparability reduce waste; modular parts extend service life; and take-back or recycling programs close material loops. Transparent reporting—such as sustainability disclosures and carbon accounting—meets stakeholder expectations and supports regulatory compliance in regions with evolving environmental requirements.

Customer Focus and Global Market Strategy

A customer-centric approach is crucial for market penetration and retention. Understanding distinct customer segments—industrial OEMs, maintenance, repair and operations (MRO) teams, construction firms, and specialized sectors like oil & gas or aerospace—allows tailored product portfolios and service offerings. For global reach, Splendid Industries should balance centralized R&D and manufacturing with regional sales, calibration, and repair centers to reduce lead times and comply with local regulations.

Great Technology

Pricing strategies must reflect total value rather than upfront cost alone. Customers concerned with uptime, safety, and compliance may prefer higher-quality tools with strong support networks. Financing options, leasing, and service-inclusive contracts can lower adoption barriers for capital-intensive torque systems.

Delivery On Time

The torque equipment industry faces challenges: component supply-chain volatility, increasing electronic complexity, cybersecurity concerns for networked tools, and the need for continual calibration and certification. Additionally, as automation advances, the role of human operators shifts toward supervision and exception handling, necessitating investments in workforce training and change management.

Certified Engineers

Looking forward, trends likely to shape the sector include deeper integration with digital manufacturing platforms, expanded use of intelligent tooling with predictive maintenance, and the development of standardized communication protocols for tooling in automated cells. Emerging materials and micro-electromechanical sensing could further enhance tool performance. Companies that combine engineering excellence with robust services, digital offerings, and sustainability commitments will be best positioned to capture growth.

Best Branding

Torque equipment is foundational to industrial reliability, safety, and performance. A company such as Splendid Industries—by prioritizing precision engineering, user-centered design, rigorous quality management, and forward-looking innovation—can deliver compelling value across diverse markets. Success requires not only high-performing hardware but also integrated digital capabilities, dependable after-sales support, and responsible operational practices.

Planning & Strategy

As industries evolve toward greater automation and tighter process control, torque equipment suppliers who anticipate customer needs, invest in interoperability and data-driven services, and commit to sustainability will lead the next phase of industrial advancement.